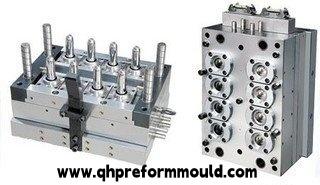

Various Cavity Numbers Moulds offer flexibility in production setups, allowing manufacturers to adjust output volumes according to demand. These designs incorporate multiple chambers within a single frame, enabling simultaneous forming of several items. Factories benefit from this arrangement by streamlining workflows and optimizing material use. Operators find that such configurations adapt well to different batch sizes, from small runs to larger quantities. This approach helps maintain consistency in shape and quality across pieces.

Imagine a bustling workshop where teams prepare for a new order. They select molds with varied chamber counts to match the project's scale. For compact needs, fewer cavities suffice, while expansive requirements call for more. This versatility reduces downtime between switches, keeping lines active. Materials flow evenly into each section, ensuring uniform results. Craftsmen appreciate how these tools handle diverse resins without complications. Adjustments come easily, with simple tweaks to pressure or temperature aligning outputs precisely.

In another scenario, a facility expands its range. They integrate molds featuring assorted cavity options into existing machinery. This integration boosts capacity without major overhauls. Workers train quickly on handling these units, mastering techniques for efficient extraction. Finished products emerge ready for packaging, minimizing post-processing steps. Reliability in daily operations stems from sturdy builds that withstand repeated cycles. Maintenance involves routine checks, preserving functionality over extended periods.

Consider the creative side of manufacturing. Designers experiment with cavity layouts to innovate product forms. Multiple slots allow testing variations side by side, fostering refinement. This method encourages exploration of shapes and sizes, leading to unique offerings. Teams collaborate on prototypes, using these molds to bring ideas to life swiftly. Feedback loops tighten, with quick iterations based on initial trials. Such agility supports market responsiveness, adapting to trends fluidly.

Environmental considerations play a role too. Efficient cavity use cuts waste by maximizing each pour. Recovered scraps reintegrate into future batches, promoting resourcefulness. Energy consumption drops as fewer runs produce equivalent volumes. Facilities adopt greener habits, aligning with broader sustainability efforts. This mindful practice appeals to partners seeking responsible suppliers.

Collaboration enhances outcomes. Engineers consult on cavity configurations tailored to specific applications. Customizations address unique challenges, like intricate details or robust structures. Prototyping phases reveal optimal setups, guiding final choices. This partnership builds trust, ensuring tools meet expectations reliably.

Quality control integrates seamlessly. Inspections occur at key points, verifying dimensions and integrity. Consistent cavity performance aids in upholding standards across outputs. Documentation tracks batches, providing traceability for audits. This systematic approach reassures clients about product dependability.

Innovation drives continuous improvement. Research into materials refines cavity durability, extending service life. New coatings reduce sticking, easing release. These advancements keep operations smooth, adapting to evolving needs. Facilities that embrace such progress stay competitive in dynamic environments.

Supply chains benefit from modular designs. Interchangeable parts simplify repairs, reducing lead times. Vendors stock common components, facilitating quick acquisitions. This preparedness minimizes disruptions, supporting steady production rhythms.

Training programs equip staff with skills for managing varied cavity systems. Workshops cover setup, operation, and troubleshooting basics. Hands-on sessions build confidence, enabling independent handling. This investment in human resources pays dividends through enhanced productivity.

Market demands fluctuate, yet flexible molds accommodate shifts effortlessly. Scaling up or down becomes routine, matching supply to orders accurately. This responsiveness fosters client loyalty, as deliveries align with timelines consistently.

Economic aspects favor these setups. Lower initial investments for versatile tools stretch budgets further. Operational savings accumulate from reduced material waste and energy use. Return on investment materializes through sustained efficiency gains.

Community impacts emerge positively. Local economies thrive when factories operate reliably, creating jobs and stimulating growth. Ethical practices in manufacturing resonate with consumers, enhancing brand reputation.

qhpreformmould stands out in providing these adaptable solutions. Their expertise guides selections, ensuring fits for diverse requirements.

For more insights into enhancing your manufacturing processes, visit Taizhou Qihong Mold Co., Ltd.: https://www.qhpreformmould.com/